|

|

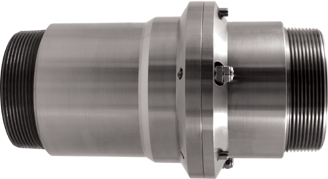

Marine Breakaway Couplings

Performance and features

应用广泛

Sequential Closure KLAW Marine Flip-Flap Valve

Technical specifications

KLAW Marine Breakaway Couplings protect assets, personnel, reputation and the environment during offshore transfer operations

Marine Breakaway Couplings minimises risks in offshore transfer

The KLAW Marine Breakaway Coupling provides an identified and safe parting point within the hose transfer system. When tensile forces exceed predetermined tolerances, the Marine Breakaway Coupling activates.

The KLAW Marine Breakaway Coupling then delivers two distinct safety features. The first is the closing of the flow of the media being transferred; the second is allowing separation of the hose transfer system. Separation relieves the hose transfer system and minimises risk of damage and spillage.

Click here to request the KLAW Marine Environment Application Guide

Minimising risk during offshore transfer

Activation may be caused by events or situations that would prove disastrous without this proven and vital part of the transfer system. Events such as vessel movement, storms and pressure surge could compromise hose transfer systems and cause damage to assets, injury to personnel, contamination of the environment and extended downtime. This might lead to disruption of operation, extensive clean-up costs, litigation and damaged reputation. The KLAW Marine Breakaway Coupling is therefore a crucial part of maintaining a reliable offshore transfer system.

Typical events

- Vessel movement and loss of Dynamic Positioning (DP).

- Pressure Surge: Caused by inadvertent downstream valve closure elsewhere in the system or over-pressurisation. The activation setting is pre-determined to suit the operating conditions.

Performance and features

[返回顶部]Double closure on activation

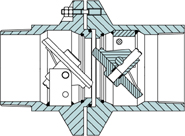

When a KLAW Marine Breakaway Coupling activates, the Flip-Flap Valve mechanism closes on both the upstream and downstream flow within the hose transfer system. This minimises spill on both sides of the hose transfer separation.

Instantaneous closure

Spill on activation is minimised by the instantaneous closure of the KLAW Flip-Flap Valve mechanism.

100% shut-off of flow

The KLAW Flip-Flap Valve mechanism provides 100% closure and therefore 100% shut-off of both upstream and downstream flow.

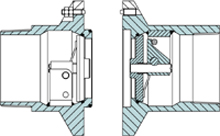

Minimum headloss

The KLAW Flip-Flip Valve is designed to deliver minimum headloss when in the locked open position within the Breakaway Coupling. This allows the coupling to provide transfer efficiencies as well as minimising the risk of spills.

Reliable performance in the marine environment

The KLAW Marine Breakaway Coupling is designed specifically to resist those bending moments and torsional forces expected from floating wave motions and the rigours of the marine environment. The design of the KLAW Marine Breakaway Coupling therefore prevents premature activation of the unit and protects the Breakstuds from fatigue.

应用广泛

[返回顶部]- Offshore supply vessels: Supply Vessels to/from Offshore Platforms

- Ship-to-ship transfer

- Ship-to-shore transfer

- Any transfer application where protection must be fitted between two sections of flexible hose.

World-wide industry standard

The Flip-Flap Valve design inside the KLAW Marine Breakaway Coupling has delivered many years of reliable and consistent performance and has proven to be the most reliable Safety Breakaway Coupling in the offshore transfer environment. The KLAW Marine Breakaway Coupling is the world-wide industry standard and is the most widely used model of its kind in the world.

Sequential Closure KLAW Marine Flip-Flap Valve

[返回顶部] |

|

| 1. Valves lock each other in open position | 2. Coupling begins to separate, Flaps rotate |

|

|

| 3. Flaps snap into the closed position | 4. Coupling parts and hose system separates |

Technical specifications

[返回顶部]Materials of Construction

Standard coupling housings are stainless steel. Other materials are available on request.

尺寸

Standard nominal bores available:

2″, 3″, 5″, 6″, 8″

The 4″ is now available in the new shorter and lighter KLAW Marine2.

Click here for Marine2 details

Pressure Ratings

Standard range design pressure 2″ = 40 BAR (580 PSI)

Standard range design pressure 3″ = 40 BAR (580 PSI)

Standard range design pressure 4″ = 30 BAR (435 PSI)

Standard range design pressure 5″ = 27 BAR (391 PSI)

Standard range design pressure 6″ = 23 BAR (333 PSI)

Standard range design pressure 8″ = 17 BAR (246 PSI)

Higher pressure and higher flow rates are available on request.

End Connections

- NPT Threaded male or female

- BSP Threaded tapered or parallel

- Flanged Connections (ANSI 150/PN16 ANSI 300/PN40)

- Weld prepared ends (Schedule 40)

- Hammer Union Fittings (Fig 100)

- Other End Connection configurations are also available on request. Contact the KLAW team for further details.

断裂载荷

Coupling break-loads can be varied to suit any particular application. Please contact KLAW for further information.

如需更多信息,请联系 KLAW

If you would like a quotation or further information you are welcome to complete our Submit Enquiry form or contact us on

+44 1373 827 100